3D Printing Materials in Egypt

3D Printing Materials Available at SolidForms

Choosing the right 3D printing material is critical, especially in Egypt’s climate. Heat, UV exposure, mechanical stress, and long-term durability all affect material performance.

At SolidForms, we don’t just print — we help you choose the correct material based on real-world use, not marketing claims.

Below is a detailed guide to the 3D printing materials we offer, including their strengths, limitations, and ideal applications.

1. PLA / PLA+

Overview

PLA is one of the most commonly used 3D printing materials due to its excellent surface finish and dimensional accuracy. PLA+ is an enhanced version with improved strength and layer adhesion.

Key Properties

- Easy to print

- High detail and clean surfaces

- Low warping

- Biodegradable base material

Limitations (Important in Egypt)

- Low heat resistance

- Can deform in hot environments (cars, outdoors)

Best Uses

- Architecture models

- Visual prototypes

- Concept designs

- Student projects

- Presentation models

👉 Recommended for indoor, non-load-bearing parts

2. ABS / ABS+

Overview

ABS is a strong, impact-resistant material commonly used in functional parts. ABS+ offers improved print stability and strength.

Key Properties

- Higher heat resistance than PLA

- Strong and impact-resistant

- Can be post-processed (sanding, acetone smoothing)

Limitations

- Requires controlled printing environment

- Not UV resistant

Best Uses

- Functional enclosures

- Mechanical parts

- Replacement components

- Parts exposed to moderate heat

👉 Good balance between cost and performance

3. ASA

Overview

ASA is similar to ABS but designed for outdoor and UV exposure, making it ideal for Egypt’s climate.

Key Properties

- Excellent UV resistance

- High heat resistance

- Long-term outdoor durability

- Stable mechanical performance

Best Uses

- Outdoor components

- Automotive parts

- Equipment housings

- Parts exposed to sunlight

👉 Recommended for outdoor use in Egypt

4. PETG

Overview

PETG combines strength, flexibility, and moisture resistance, making it one of the most versatile materials available.

Key Properties

- Strong and slightly flexible

- Moisture and chemical resistant

- Better heat resistance than PLA

- Good layer adhesion

Best Uses

- Functional prototypes

- Containers and housings

- Mechanical parts

- Parts exposed to humidity

👉 Excellent all-round material

5. TPU (Flexible Material)

Overview

TPU is a flexible, rubber-like material used for parts that need elasticity and impact absorption.

Key Properties

- Highly flexible

- Excellent impact resistance

- Vibration damping

- Wear resistant

Best Uses

- Gaskets and seals

- Protective covers

- Flexible joints

- Shock-absorbing components

👉 Ideal when rigidity is not desired

6. PC (Polycarbonate)

Overview

Polycarbonate is a high-performance engineering material known for strength and heat resistance.

Key Properties

- Very high impact strength

- High heat resistance

- Strong and rigid

Limitations

- More complex printing process

- Higher cost

Best Uses

- Engineering parts

- Structural components

- High-temperature environments

- Industrial applications

👉 Used when maximum strength is required

7. Nylon (PA)

Overview

Nylon (Polyamide) offers excellent mechanical strength and wear resistance, widely used in industrial applications.

Key Properties

- High strength

- Fatigue resistant

- Low friction

- Durable under repeated stress

Limitations

- Moisture sensitive

- Requires proper storage and printing control

Best Uses

- Gears

- Bearings

- Mechanical components

- Functional parts under stress

Carbon Fiber Reinforced Materials (CF)

Carbon fiber filaments offer significant strength and stiffness improvements over standard plastics.

8. PA-CF (Carbon Fiber Nylon)

- Extremely stiff and strong

- High heat resistance

- Industrial-grade performance

Best for:

Structural parts, jigs, fixtures, high-load components

9. PETG-CF

- Improved stiffness over PETG

- Better dimensional stability

- Reduced warping

Best for:

Functional parts requiring rigidity with moderate cost

10. PLA-CF

- Excellent surface finish

- Very stiff

- Easy to print compared to other CF materials

Best for:

Visual structural parts, jigs, and fixtures

Material Selection Guidance

Not sure which material to choose?

At SolidForms, we evaluate:

- Load and stress

- Heat exposure

- Indoor vs outdoor use

- Required flexibility

- Budget constraints

👉 We recommend, not upsell.

3D Printing Materials in Egypt — Done Professionally

SolidForms offers one of the widest material selections in Egypt, supported by professional-grade machines and real-world testing.

If you need help selecting the right material for your project, contact us — we’ll guide you based on function, environment, and budget.

For More Info about Pricing, tap here -->

For More Info about Materials, tap here -->

For More Info about 3D Printing in Egypt, tap here -->

For More Info about 3D Print Farms, tap here -->

For More Info about Student Projects, tap here -->

For FAQs, tap here -->

Our Bestsellers

-

Headphone Stand - Iron Man

Vendor:SolidFormsRegular price LE 1,399.00 EGPRegular price -

Broken Greek Column Bookend

Vendor:SolidFormsRegular price LE 549.00 EGPRegular priceBroken Greek Column Bookend

Regular price LE 549.00 EGPRegular priceBroken Greek Column Bookend

Regular price LE 549.00 EGPRegular price -

Custom Dog Tag - Personalized Pet ID Tag with Name

Vendor:SolidFormsRegular price LE 149.00 EGPRegular priceLE 200.00 EGPSale price LE 149.00 EGPCustom Dog Tag - Personalized Pet ID Tag with Name

Regular price LE 149.00 EGPRegular priceLE 200.00 EGPSale price LE 149.00 EGPCustom Dog Tag - Personalized Pet ID Tag with Name

Regular price LE 149.00 EGPRegular priceLE 200.00 EGPSale price LE 149.00 EGPSale -

Headphone Stand - "عصام"

Vendor:SolidFormsRegular price LE 1,399.00 EGPRegular priceHeadphone Stand - "عصام"

Regular price LE 1,399.00 EGPRegular priceHeadphone Stand - "عصام"

Regular price LE 1,399.00 EGPRegular price -

Suriel - Tea Time Edition (ACOTAR)

Vendor:SolidFormsRegular price LE 649.00 EGPRegular price -

Sale

SaleEngine Keychain

Vendor:SolidFormsRegular price LE 99.00 EGPRegular priceLE 150.00 EGPSale price LE 99.00 EGPSale -

Dragon Book Nook

Vendor:SolidFormsRegular price From LE 1,699.00 EGPRegular priceDragon Book Nook

Regular price From LE 1,699.00 EGPRegular priceDragon Book Nook

Regular price From LE 1,699.00 EGPRegular price -

SolidForms Lamp

Vendor:SolidFormsRegular price LE 1,400.00 EGPRegular priceSolidForms Lamp

Regular price LE 1,400.00 EGPRegular priceSolidForms Lamp

Regular price LE 1,400.00 EGPRegular price -

Keychain Light-Up Photo

Vendor:SolidFormsRegular price LE 150.00 EGPRegular priceLE 200.00 EGPSale price LE 150.00 EGPSale -

Sale

SaleInfinity Cube

Vendor:SolidFormsRegular price LE 89.00 EGPRegular priceLE 120.00 EGPSale price LE 89.00 EGPInfinity Cube

Regular price LE 89.00 EGPRegular priceLE 120.00 EGPSale price LE 89.00 EGPInfinity Cube

Regular price LE 89.00 EGPRegular priceLE 120.00 EGPSale price LE 89.00 EGPSale -

Sale

SaleThumb Book Holder

Vendor:SolidFormsRegular price LE 59.00 EGPRegular priceLE 80.00 EGPSale price LE 59.00 EGPThumb Book Holder

Regular price LE 59.00 EGPRegular priceLE 80.00 EGPSale price LE 59.00 EGPThumb Book Holder

Regular price LE 59.00 EGPRegular priceLE 80.00 EGPSale price LE 59.00 EGPSale -

Screw Fidget Keychain

Vendor:SolidFormsRegular price LE 79.00 EGPRegular priceLE 100.00 EGPSale price LE 79.00 EGPScrew Fidget Keychain

Regular price LE 79.00 EGPRegular priceLE 100.00 EGPSale price LE 79.00 EGPScrew Fidget Keychain

Regular price LE 79.00 EGPRegular priceLE 100.00 EGPSale price LE 79.00 EGPSale -

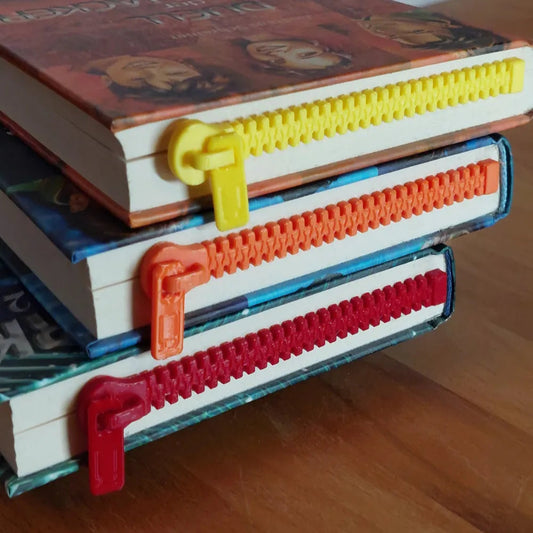

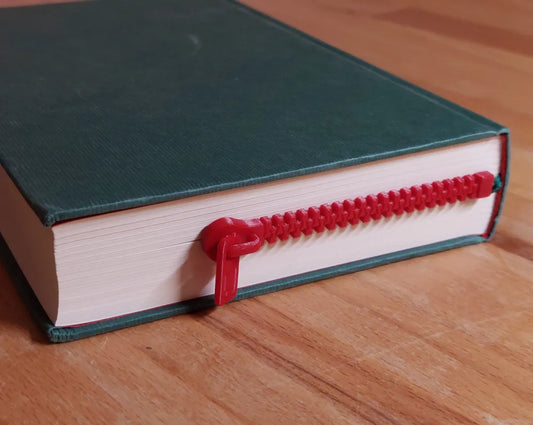

Realistic Zipper Bookmark

Vendor:SolidFormsRegular price LE 79.00 EGPRegular priceRealistic Zipper Bookmark

Regular price LE 79.00 EGPRegular priceRealistic Zipper Bookmark

Regular price LE 79.00 EGPRegular price -

Sale

Sale -

Formula 1 Multicolor Keychain - F1 Tyre - Hard Plastic

Vendor:SolidFormsRegular price LE 149.00 EGPRegular priceLE 200.00 EGPSale price LE 149.00 EGPFormula 1 Multicolor Keychain - F1 Tyre - Hard Plastic

Regular price LE 149.00 EGPRegular priceLE 200.00 EGPSale price LE 149.00 EGPFormula 1 Multicolor Keychain - F1 Tyre - Hard Plastic

Regular price LE 149.00 EGPRegular priceLE 200.00 EGPSale price LE 149.00 EGPSale